Why your facility’s pools should combine regenerative media filtration and UV technology to tackle different challenges.

Whether you dog paddle or have an elegant butterfly stroke, aquatics activities are both fun and great for your health. With millions of annual visits to aquatics facilities around the U.S., it’s important as an industry we work collectively to ensure a clean and safe environment for swimmers and spectators alike.

High swimmer loads experienced in commercial and competitive pools can easily overwhelm traditional methods of filtration and disinfection. In fact, according to the CDC, “one in eight pools closed immediately on routine inspection for critical health and safety problems.”1

Many aquatics facilities are therefore coupling advanced technologies, such as regenerative media filtration (RMF) and ultraviolet (UV) disinfection, to tackle various operational, microbiological and environmental challenges in an attempt to provide swimmers a safe and sustainable experience.

Regenerative Media Filtration — Delivering Clean and Clear Water. Sand and regenerative media filters both operate on the principle of mechanical filtration — although, filters trap particulates on the surface of hundreds, or even thousands, of flexible tubes coated with perlite media. Compared to an equally sized sand filter, an RMF filter contains nearly nine to 12 times more effective filtration surface area, thereby making it more efficient and compact.

When the perlite becomes overloaded, the RMF technology regenerates by “bumping,” a process in which no water is lost to municipal waste. In addition to providing superior and efficient micron particulate removal, RMF technology significantly reduces the amount of water wasted to drain. As a result, savings can be realized in several key areas:

- Up to 90% in water savings.

- Up to 50% in energy savings.

- Up to 30% in chemical savings.

- Up to 75% in space savings.

- Up to 95% reduction in particulate.

A Better Disinfection Alternative — a Pool Doesn’t Have to Smell Like a Pool. Chlorine is used as a primary disinfection method to keep pools clean and safe, but often at a cost. Chlorine in pool water reacts with organic compounds to form disinfection byproducts such as mono-, di- and tri-chloramines. Volatile in nature, chloramines off-gas and concentrate at the water/air interface, where swimmers breathe, causing burning eyes and respiratory issues that can affect both performance and long-term health.

Chloramines further dissipate into the natatorium, causing corrosion and that offensive “chlorine smell” we are all familiar with. In addition, operators experience storage and handling related concerns. What if it were possible to reduce chemical usage and simultaneously offer improved swimmer protection rather than by using chlorine alone?

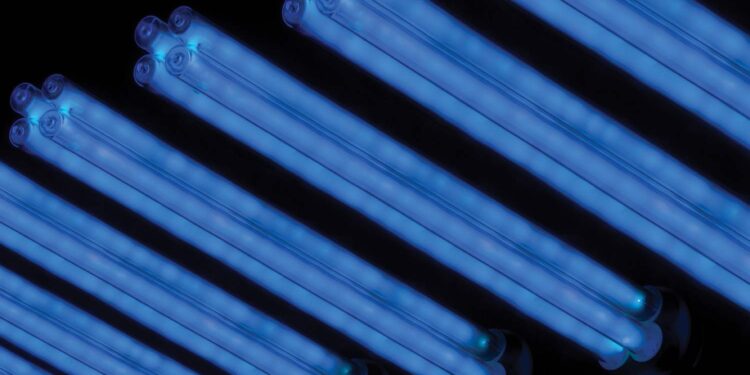

UV disinfection works in primarily two ways: first, inactivating chlorine-tolerant pathogens like cryptosporidium and reducing the risk of recreational waterborne illnesses (RWIs) and second, destroying the DNA of undesirable disinfection byproducts such as chloramines.

UV light inactivates microorganisms like bacteria, viruses, molds and other pathogens without the use of chemicals. UV light inflicts permanent damage to DNA and RNA contained in all living species. Once damaged, chlorine resistant organisms such as cryptosporidium are unable to sustain routine cell functions such as respiration, food assimilation and replication. With cells rendered non-viable, the organism quickly dies.

The Ultimate Duo to Tackling Today’s Concerns While Meeting Tomorrow’s Objectives. Coupling RMF’s capabilities at removing particulate down to one micron not only helps create a cleaner and clearer pool — increasing the transmittance of UV light — but increases the effectiveness of the UV technology. It enables more of the UV light to disable the various microorganism contaminants found in the pool, such as cryptosporidium, and destroy chlorine disinfection byproducts such as chloramines.

On their own, RMF and UV technology enable improved water and air quality, while also meeting chemical, energy and water reduction objectives. When used together, those benefits are multiplied, not only creating a more efficient facility that minimizes maintenance and operation, but also provides more safety and comfort for bathers.

Scott Hyland is an expert in commercial water filtration, specializing in competition pools, waterparks, aquariums and other large aquatics facilities. He has more than 20 years of experience providing solutions for recreational water facilities across the U.S., and North, Central and South America. Scott can be reached at scott.hyland@evoqua.com.